Blow molding designs these days can hit really tight tolerances, sometimes getting down to less than 0.1mm in mass production runs. The kind of precision we're talking about matters a lot when making things like car fuel tanks or medicine bottles, because even small size variations (around 2% off) could cause big problems later on. Manufacturers are starting to rely heavily on simulation software too. These advanced tools can forecast how materials will behave during the process with pretty good accuracy, maybe around 90% give or take. And this means companies don't have to go through so many test cycles anymore, cutting down on wasted time and materials by roughly a third compared to older techniques.

Multi-cavity molds with temperature-controlled zones maintain ±0.05mm wall thickness uniformity over 50,000+ production cycles. A 2024 Gauge R&R study found custom tooling improves measurement reproducibility by 28% in food-grade packaging. Real-time pressure sensors detect parison thickness variations as small as 0.3%, allowing immediate in-cycle adjustments to ensure consistency.

Vision systems that automate inspection can check around 120 parts every minute and spot tiny flaws measuring just 40 microns squared thanks to machine learning algorithms. Factories that implement these systems along with their SPC dashboards find they diagnose problems 41 percent quicker than before. The real money saver comes from reduced waste materials during bottle manufacturing processes where waste drops about 18%. Plus these same systems help manufacturers stay compliant with those strict ISO 13485 requirements needed for medical device production. Many plant managers actually tell us this setup makes quality control much less stressful day to day.

One major medical device maker saw a dramatic drop in IV bag port failures after switching to cavity pressure optimized molds. The improvement was around 60%, which made a real difference in product reliability. Their special blow molding setup kept variations under 0.08mm across over a million units produced, something absolutely essential for maintaining those sterile conditions required in healthcare settings. Implementing AI based dimensional checks allowed them to shorten their validation process by nearly two months. This shows just how important precise engineering becomes when scaling up production while still meeting strict regulatory standards that the industry faces daily.

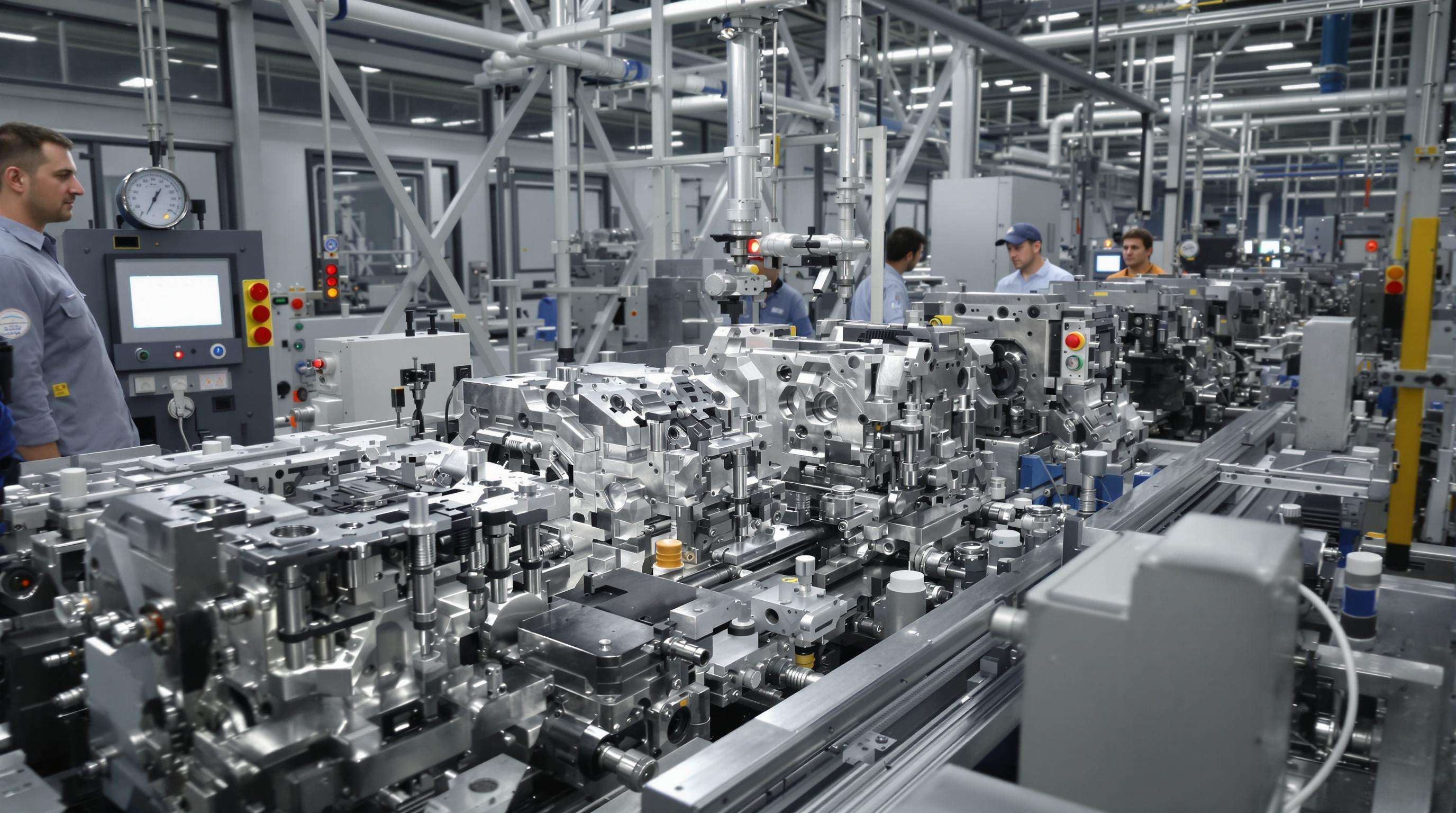

Custom blow-molding design allows manufacturers to move beyond standardized packaging, enabling tailored geometries for diverse applications—from child-resistant closures in pharmaceuticals to lightweight, sustainable containers for beverages.

Today's blow molding machines can adjust bottle heights from around 50mm up to 500mm pretty quickly, along with changing neck finishes and base designs all without needing complete new tooling setups. A recent look at the industry in 2023 found that nearly two thirds of food companies are now using these modular mold systems for flexible packaging across their different products. What makes this so valuable is how much faster it gets things done on the production floor. Changeovers between different stock keeping units take about 12 to 15 percent less time than with older traditional methods, which really adds up when running multiple product lines through the same facility.

We're seeing some pretty cool design changes lately like those angled handles on big industrial chemical containers, asymmetrical panels that help people get a better grip on sports bottles, and these neat multi-chamber setups in high end skincare serums. These kinds of special shapes are catching on because consumers want both practicality and something that stands out on store shelves. Cosmetic companies have actually noticed their products stand out about 25 percent more when they come in unusual containers, which makes sense given how crowded beauty sections can get nowadays.

Conformal cooling channels and hybrid metal-polymer molds now achieve ±0.15mm wall thickness uniformity and support complex surface textures. These advancements eliminate many historical design constraints:

| Capability | Traditional Limits | Advanced Solutions |

|---|---|---|

| Undercut Complexity | 0-1 level | 3+ level nested cores |

| Surface Finish | Gloss/Matte | Micro-textured patterns |

| Draft Angles | ≥3° | 0.5° with ejector pins |

This evolution in mold engineering enables an 89% first-pass success rate for complex medical housings, up from 55% with conventional tooling.

Modular blow-molding systems with interchangeable components reduce retooling time by up to 70%, allowing seasonal or limited-edition packaging to be deployed in 3–4 weeks instead of 12+. This agility is vital in fast-moving sectors like beverages, where 64% of consumers prioritize limited-edition designs. Custom equipment thus enables rapid alignment with shifting market demands.

Adaptive blow-molding systems support localized production strategies. A 2024 study of 450 manufacturers showed regionalized tooling reduced logistics costs by 22% and improved compliance with local sustainability regulations. For niche markets such as organic cosmetics, custom engineering enables unique forms—like hexagonal bottles or ergonomic dispensers—that standard molds cannot produce.

Specialty packaging saw growth at nearly double the rate of the general market last year, mainly because companies started embracing custom blow molding techniques. New businesses that implement this approach typically get their products to market about 40 percent quicker than competitors stuck with standard tooling solutions. The ability to rapidly prototype and adjust designs makes all the difference when it comes to keeping customers around. Brands that stand out through unique packaging formats have noticed something interesting too - their consumer base tends to stick with them roughly 29% longer than average. This connection between creative packaging and loyal customers is becoming increasingly clear across the industry.

Tailored mold engineering reduces cycle times by 12–18% by aligning tooling with specific material behavior, eliminating redundant cooling phases without sacrificing strength. In high-volume packaging lines, this efficiency gain translates to 400–600 additional units per 8-hour shift compared to standard systems.

Automated material handling and in-line inspection reduce labor costs by 30–45% across multi-stage operations. PLC integrations enable real-time control of wall thickness and pressure, minimizing manual adjustments. This automation frees operators to focus on process optimization rather than routine monitoring.

Although custom tooling requires a 20–35% higher initial investment, manufacturers typically achieve ROI within 12–18 months due to lower scrap rates and energy use. A 2023 analysis of 47 facilities found that after three years, custom blow-molding systems delivered 9% lower per-unit costs than retrofitted legacy equipment.

Advanced mold flow analysis reduces material overuse by 18–22% in complex features such as handles and threaded closures. Virtual prototyping eliminates trial-and-error waste, particularly in medical container production requiring ±0.15mm accuracy. In medium-scale operations, this precision reduces annual polymer consumption by 7–12 tons.

Precision in blow molding designs is critical for manufacturing components like car fuel tanks or medicine bottles, where small size variations could lead to significant problems. Achieving tight tolerances ensures product reliability and safety.

Custom mold tools, such as multi-cavity molds with temperature-controlled zones, achieve consistent repeatability by maintaining uniform wall thickness and making in-cycle adjustments using real-time pressure sensors.

Innovative designs in beverage and cosmetic packaging include angled handles on containers, asymmetrical panels for better grip, and multi-chamber setups. These designs cater to consumer preferences for practicality and standout products.

Advanced mold engineering, including conformal cooling channels and hybrid metal-polymer molds, overcomes traditional design limits by allowing complex geometries, enhanced surface textures, and precise draft angles.

Integrating automation in blow-molding systems reduces labor costs by enabling real-time control and minimizing manual adjustments. Automation enhances efficiency and allows operators to focus on optimizing the process instead of routine monitoring.

Hot News

Hot News2024-10-29

2024-09-02

2024-09-02

Copyright © 2024 Changzhou Pengheng Auto parts Co., LTD